Your manufacturing floor runs on precision, but your digital systems speak different languages. Quality data sits isolated. Production approvals stall in email. Supply chain visibility evaporates between facilities.

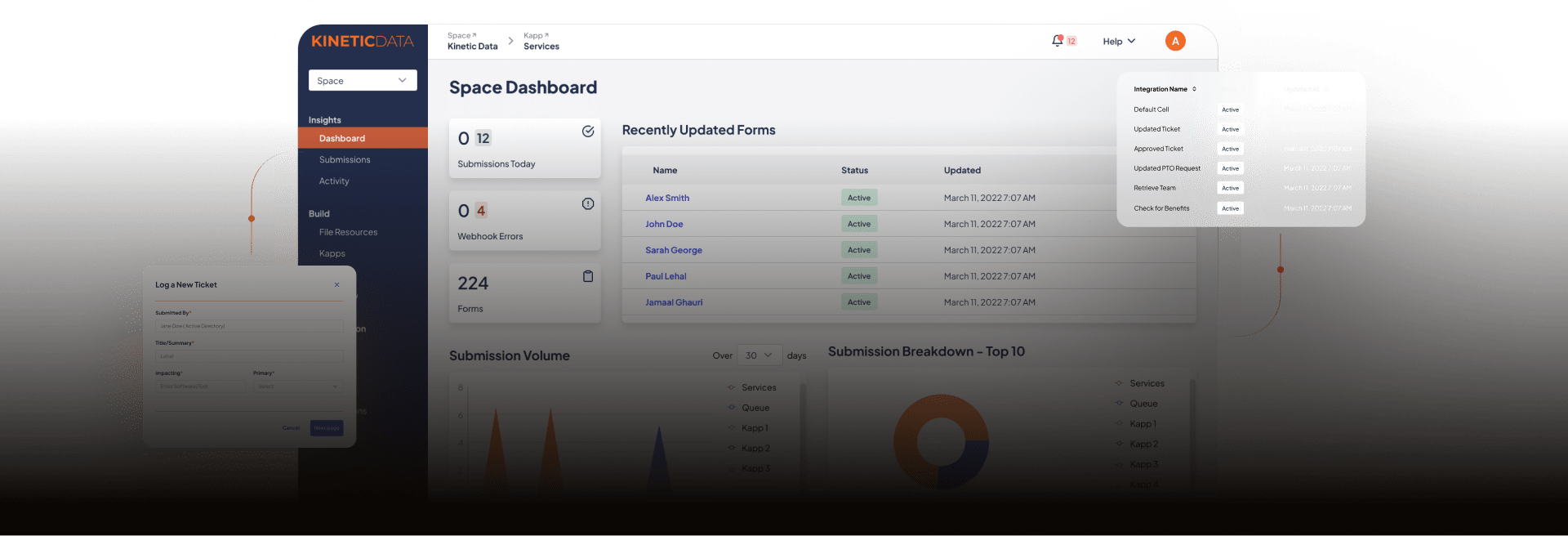

Kinetic orchestrates your entire manufacturing ecosystem—from shop floor to C-suite—without replacing the infrastructure you've invested decades building. We transform industrial chaos into operational clarity.